It's time to never lose a sale from stockouts again

Jul 19, 2019

Scroll to find out more

Jul 19, 2019

Scroll to find out more

It’s frustrating when the product you want is out of stock. Whether it’s online or in the supermarket, this seems to happen to me quite often. Just last week I was disappointed to find my favourite cereal missing from the shelf. It sucked, but I chalked it up to bad luck and had porridge instead.

I knew I wasn’t the only one frustrated at missing products, but it wasn’t until I’d spoken with Daniel Corsten that I quantified what stockouts mean for customers.

Corsten is a Professor of Technology and Operations at IE Business School, a Global Top 10 MBA Business School. As one of the world’s experts on the supply chain, he led a huge survey looking into the effects of out of stock.

After surveying 71,000 customers in 29 countries, he found that when buyers saw their product missing, 35% of them went elsewhere or abandoned the shop altogether. I was stunned by how strongly customers react to missing stock.

By contrast, some retailers I’ve spoken to see stock-outs as something they just have to live with, a reality of supply chain management. But hearing from Corsten, I’ve learned that’s not the case. In fact, retailers have more power over their stock than they might think.

“We found that retailers themselves are responsible for most stock-outs…72% of stock-outs were due to faulty in-store ordering and replenishing practices,” says Corsten.

If companies take control of their supply chain, they can improve their efficiencies and reduce out-of-stock outcomes.

And how can they do this? By perfecting their OTIF metric.

OTIF stands for ‘On Time In Full’. It’s a metric you can apply as a percentage of your customer orders. ‘On Time’ refers to how punctual your order was, while ‘In Full’ refers to its accuracy. But it’s important to remember that it’s not just a delivery metric, OTIF applies to your organisation as a whole, from sales to shipment and purchasing.

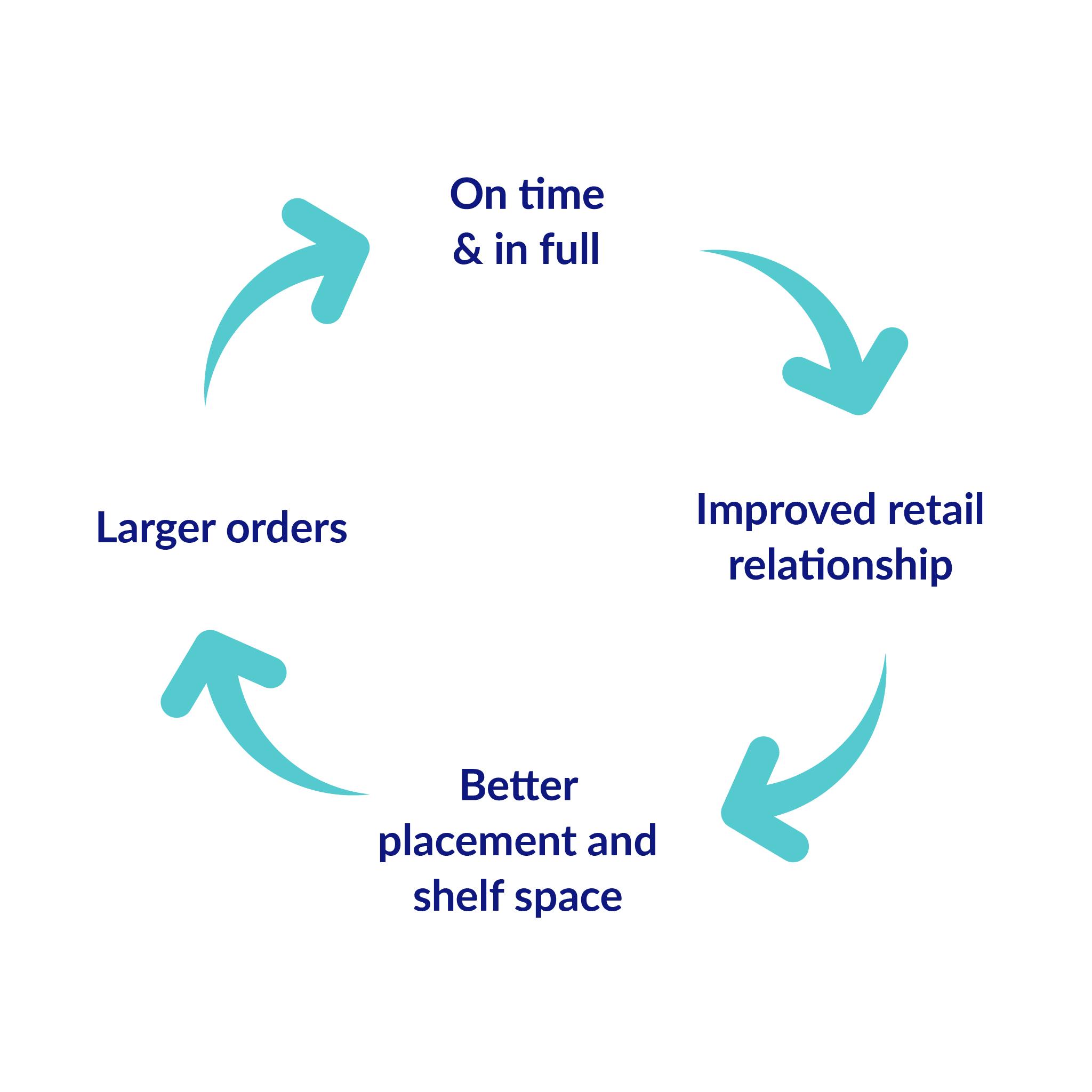

Increasing OTIF not only increases revenue but reduces costs. Let’s take a retail example. When products are ordered and shipped correctly, relations between suppliers and retailers improve. This means retailers give suppliers better shelf placement, which leads to higher orders and drives revenue. This, in turn, incentivises suppliers to maintain efficiency, and so a higher OTIF percentage continues. It’s the same story for FMCG, manufacturing or other industries.

What we see is a positive feedback loop that goes like this:

OTIF is also effective because it encourages operational excellence. Delivering higher OTIF demands greater internal collaboration between functions. For example, the sales team needs to relay precise data to the operations team who handle the order. Operations need to pass on this information to purchasing who can forecast future transactions. Everyone needs to share the same, accurate data – at Zencargo, we call this ‘the single version of the truth’. If everyone gets this right, sales go up and costs go down.

OTIF drives operational efficiency, which makes for cost saving opportunities across the board.

Now that information sharing is accurate and seamless, purchasers can predict what they need and avoid buying more than they need. More than that – you won’t have stock sitting idly in your warehouse. This means more space, but also more cash you can invest back into the company. Higher OTIF leads to smarter decisions, greater cohesion and more liquidity for the boardroom. That’s how this metric affects the whole company, from the CFO to the delivery driver.

The first thing you need to do is get real-time visibility into your supply chain. This helps because you can see blockages as they happen, which means you can divert resources to keep goods moving and maximise your on-time rates. Zencargo’s dashboard makes it easy for internal stakeholders to access and share accurate, real-time data when it matters most.

Secondly, you need technology to provide analytics for internal teams to share a ‘single version of the truth’. This empowers seniors leaders, like the CFO, to make informed decisions about where to steer the company, and where to invest. Again, this is where Zencargo’s powerful analytics can empower key decisions, help you spot opportunities and get closer to the customer.

The most successful businesses are ones who make their supply chain a boardroom issue. OTIF has influence over more than just operations; it can impact revenue, liquidity, purchasing – even brand reputation. Supply chain decisions must be taken at the top and consider more than just the costs, because C-suite leaders who invest more in their supply chain and increase their OTIF, reap big rewards.

OTIF is just one performance metric, but it shows how influential the supply chain can be for a company to succeed. In the short time I’ve been here, I’ve already seen how Zencargo has helped businesses bring their teams together and enable smarter supply chain decisions. This leads to enhanced customer experience, higher revenues and faster growth.

If you’re looking to optimise your supply chain to grow your business, please get in touch.

We are excited to welcome supply chain expert and industry leader Anne-Sophie Fr...

Zencargo’s ultimate goal is to disrupt the trillion-dollar shipping industry. Ho...

Hello, my name is Tanushree, and I’m the Marketing Manager leading the Benelux r...